How To Measure Thread Size With Caliper

Round to the nearest number so you have 3 decimal places. Here are those numbers and their decimal equivalent.

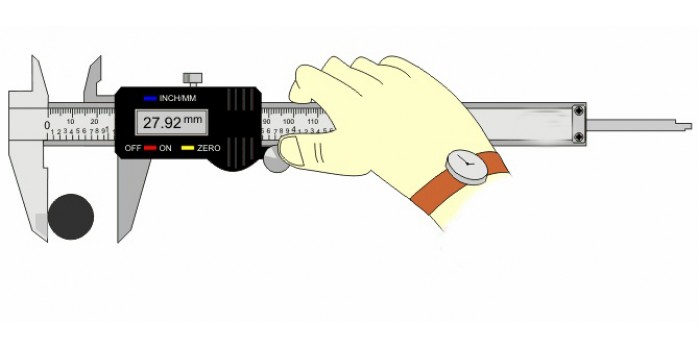

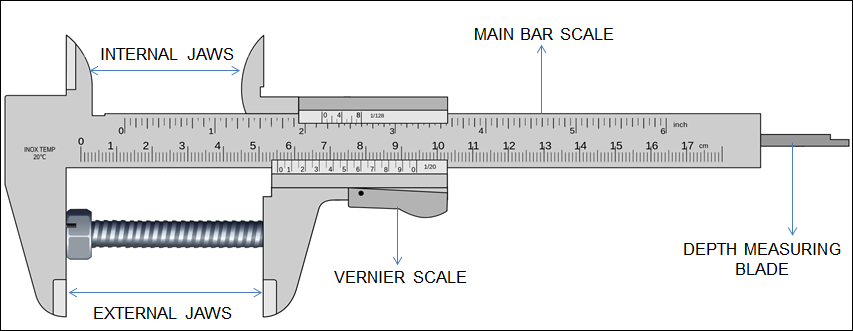

Use a caliper measuring tape or ruler to measure the thread diameter of a male thread or female thread.

How to measure thread size with caliper. This number will help determine the thread dimension. Look for the nominal size just above the 0 point on the caliper. In many common thread designs where the peak and trough of the thread are the same shape the two diameters will be equivalent.

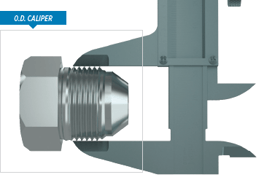

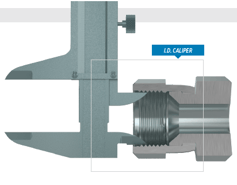

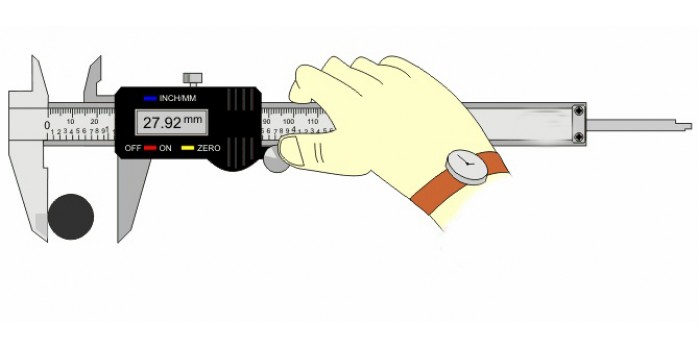

Before you remove the caliper from the hole press the button to zero the caliper while it is set to the diameter of the hole. A caliper is used to measure the OD. Worn threads are usually undersize.

Of a male thread and ID. Theres another way to tell whether you have tapered or straight threads if you are working with Swagelok parts. Measure the outer diameter of the eye with the bolt gauge or digital caliper.

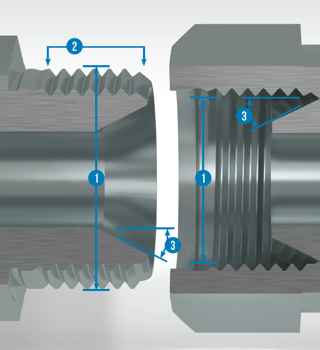

Above diagram shows about 12. Compare the OD and pitch with the thread data chart to establish the thread. Measure the thread pitch with bolt gauge or digital caliper.

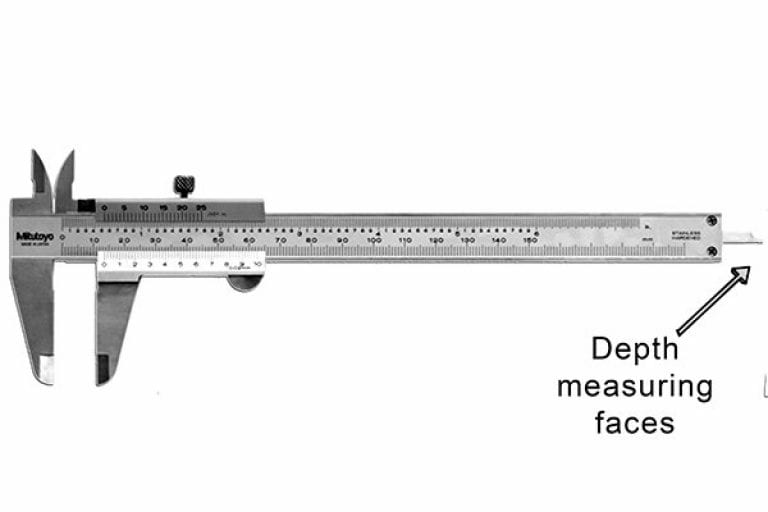

Measure the length from under the shoulder to the end. For fasteners where the head usually sits above the surface the measurement is from directly under the head to the end of the fastener. Its easiest to measure this with a caliper but you can also measure it with a ruler.

The threads of a used fitting can become worn and distorted so the measurements may not be exact. That would mean you have straight threads. When measuring a female pipe thread fpt measure the od of the pipe itself and subtract ¼ inch to find the correct pipe thread size.

2 Second use a thread pitch gauge to identify the number of threads per inch. Find the closest match on the adjacent chart thread OD and pitch combine into a thread callout such as M12 x 15 indicating a 12mm OD with 15mm pitch. For metric connections measure the distance between threads.

Of a female thread. Internal Threads - Sump Holes Using the caliper measure the Minor Diameter. If you get three different measurements you have tapered threads.

If the measurements are the same you have straight threads. Measure the inner diameter of the eye with the Weatherhead gauge. One revolution through a fixed nut the screw moves by one pitch of the thread A Circular scale marked with n equal parts is attached to the screw and each division on it measures a length equal to pitchnA linear scale with graduations in mm and 05mm is engraved on the barrel.

For fasteners that are designed to be countersunk the measurement is made from the point on the head where the surface of the material is to the end of the fastener. When comparing your measurements with those on our charts it should be remembered that threads can become worn and distorted from use and you may not compare exactly to the figures in the tables. Find the pitch or TPI using the Screw Thread gauges.

Use the inside jaws to measure the diameter of one of the holes. Measure the diameter of the thread. Determine the thread OD male thread or ID female thread using calipers.

How to Measure Threads 1 First use a combination ODID. Count the number of threads in 1 inch to get the thread spacing value. We use our calipers to measure the first fourth and last crests.

Caliper to measure the thread diameter. For male threads measure the outside diameter od. Use this procedure to measure the center distance between two holes of equal diameter.

Take the circumference measurement of your pipe and divide it by pi to reduce your measurement to a decimal value. Use the inside jaws to measure the diameter of one of the holes. Use a caliper measuring tape or ruler to measure the thread diameter of a male thread or female thread.

When measuring a female pipe thread fpt measure the od of the pipe itself and subtract inch to find the correct pipe thread size. Measure the inner diameter ID of the female thread and the outer diameter OD of the male thread. For example a 34 npt pipe thread has an outside diameter of.

Use a caliper measuring tape or ruler to measure the thread diameter of a male thread or female thread. Mean diameter is the average diameter of the bearing surface - or more accurately twice the average distance from the centreline of the thread to the bearing surface.

How To Measure Screw Size With Calipers Arxiusarquitectura

How To Measure Screw Size With Calipers Arxiusarquitectura

How To Measure Screw Size With Calipers Arxiusarquitectura

How To Measure Screw Size With Calipers Arxiusarquitectura

Measuring Screw Thread Diameter And Pitch Using A Vernier Caliper Accu Tutorials Youtube

Measuring Screw Thread Diameter And Pitch Using A Vernier Caliper Accu Tutorials Youtube

Cable Wire Wire Rope Digital Caliper Wire Cable Diameter Measurement Roktools

How To Measure Threads In Three Steps

How To Measure Threads In Three Steps

Definition And Parts Of A Vernier Caliper Vernier Caliper Vernier Calipers

Definition And Parts Of A Vernier Caliper Vernier Caliper Vernier Calipers

How To Measure Threads In Three Steps

How To Measure Threads In Three Steps

3 Easy Ways To Measure Thread Wikihow

3 Easy Ways To Measure Thread Wikihow

3 Easy Ways To Measure Thread Wikihow

3 Easy Ways To Measure Thread Wikihow

How Do You Use A Vernier Caliper To Measure Depth Wonkee Donkee Tools

How Do You Use A Vernier Caliper To Measure Depth Wonkee Donkee Tools

3 Easy Ways To Measure Thread Wikihow

3 Easy Ways To Measure Thread Wikihow

3 Easy Ways To Measure Thread Wikihow

3 Easy Ways To Measure Thread Wikihow

Can Vernier Caliper Measure Internal Diameter Quora

How To Measure A Bolt Ricks Free Auto Repair Advice Ricks Free Auto Repair Advice Automotive Repair Tips And How To

How To Measure A Bolt Ricks Free Auto Repair Advice Ricks Free Auto Repair Advice Automotive Repair Tips And How To

How To Measure Using Metric Vernier Caliper

How To Measure Using Metric Vernier Caliper

How To Measure Threads In Three Steps

How To Measure Threads In Three Steps

Comments

Post a Comment